- Understand requirement and propose optimum solution

- Expertise in handling large turn-key projects

- Complete techno-commercial support

- Technology first approach

Expertise in handling large turn-key projects

Complete techno-commercial support

Technology first approach

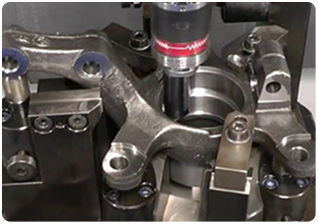

- Machining process sequence, machine selection and feasibility reports

- Time estimate, tooling and fixture proposals

- Component prove-out for cycle time, accuracy and process capability

- Training in machine operation and programming

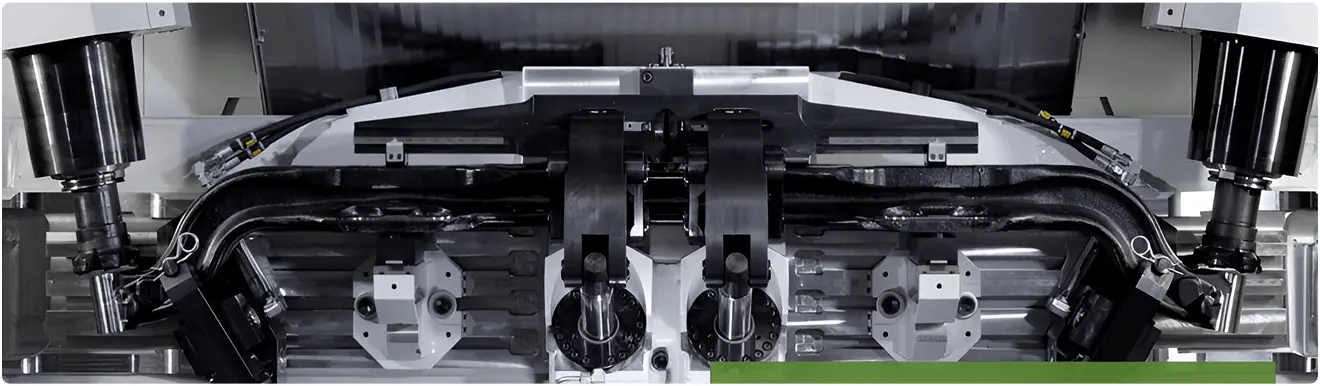

- Turnkey solutions and system engineering for machining lines

- Improvement exercise in existing process and tooling

- Site preparation for new installation

- Machine installation and commissioning

- Warranty and post warranty support

- Complete spare parts cycle management

- Operator training

- Annual maintenance contract

- Preventive maintenance contract

Intelmac Machine Tools Pvt. Ltd. is a flagship of the organization ‘Group Intelmac’. Founded in 1981, it is one of the few trusted solution partners in the business of sales and services of Globally renowned Machine Tools technology.

We offer a wide range of Machine Tools Solutions from Japan, Europe, Taiwan, Korea, etc, including Machining Centers, Turning Centers, Grinding Machines, Horizontal and Vertical Borers, Double Column Machining Centers, Multitasking Machines, CNC Bar

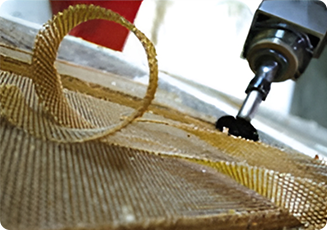

Automats, Cold rolling Machines and special machines for special applications of composites in aerospace.

The corporate office is at Pune, a prominent industrial city close to Mumbai. Our branches cover major industrial zones across India to ensure proximity to customers for providing technical services.

Applied Industries

-

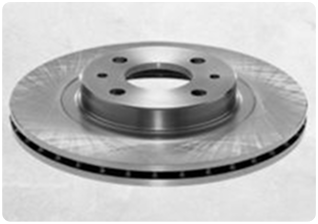

Automotive

-

Aerospace

-

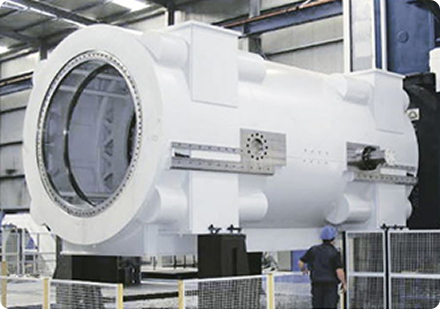

Energy

-

Railways

-

Die-Mould

-

Oil & Gas

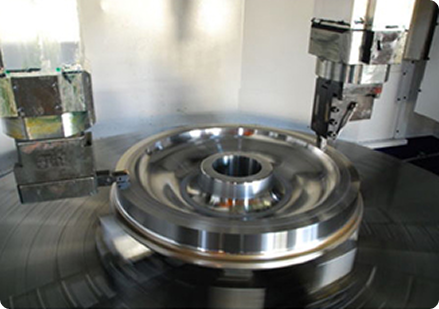

Automotive

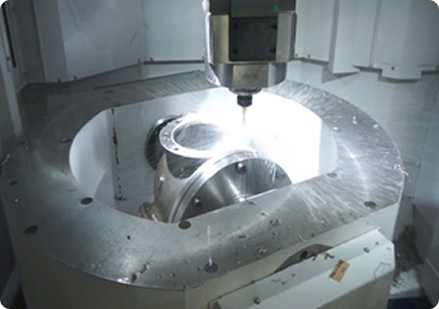

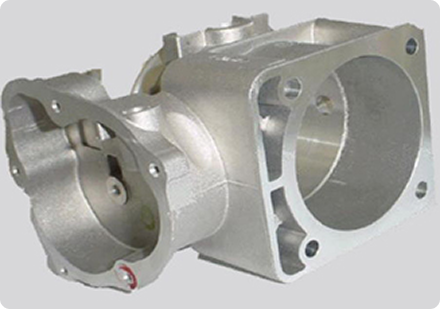

Machine tools are indispensable in the automotive industry for creating high-precision components that ensure vehicle performance and reliability manufactured from CNC Lathes, Machining centres, Boring and Grinding machines.

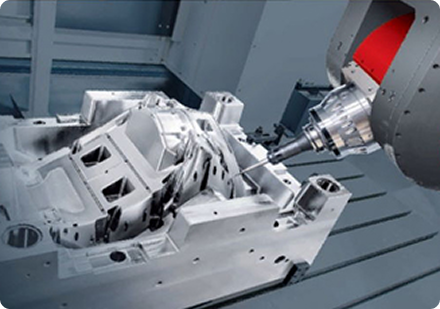

Aerospace

Machine tools are essential for manufacturing aerospace parts, particularly CNC 5-axis vertical & horizontal machining centres and turning centres. These machines capable for high-volume production, reduced waste, and achieve tight tolerances critical for aerospace applications.

Eg. Parts like engine parts, landing gear, fuselage panels, wing structures and airframe structures

Wind Energy

Machine tools such as CNC vertical turning/boring, horizontal boring, 5 axes CNC machines are essential for the manufacturing, assembly, and maintenance of various wind turbine components, particularly those requiring precise shaping and finishing.

Eg. Parts such as blades, hubs, and nacelles

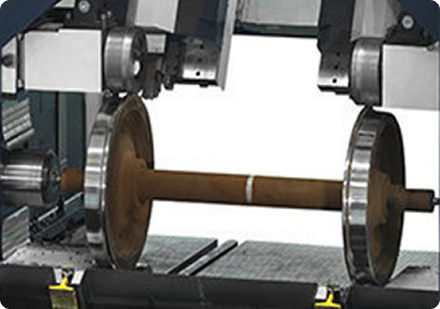

Railways

Machine tools are essential for the manufacturing and maintenance of railway bogie parts, with common operations including cutting, machining, and specialized processes like gantry milling and CNC machining for components.

Eg. Parts such as bogie frames, main frame, side frame, engine blocks/crankcases etc.

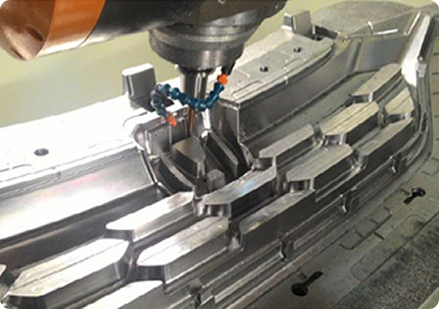

Die-Mould

Die mold parts require high precision and intricate designs that shape materials in manufacturing processes like stamping, forging, injection molding, and casting. Manufacturing these parts thru machine tools like CNC 5 axes, double column / Gantry machines etc. as their accuracy directly impacts the quality and consistency of the final products.

Eg. Parts for automotive, electronics, and consumer goods, bottles, containers, car body parts, appliances, medical devices and metal components

Oil & Gas

CNC Machine tools are crucial for manufacturing high-precision and durable parts used in the oil and gas industry, which requires components to withstand extreme conditions like high pressure, temperature, and corrosive environments. These machines are used for a variety of operations like turning, milling, grinding, and deep hole drilling to produce critical components.

Eg. Parts like Valves and valve components, Pumps and pump components, Flanges and fittings, Hydraulic equipment components etc